Coronavirus drives Chinese adoption of autonomous delivery and automation

As China finds itself isolated from the world by the coronavirus epidemic, meeting increased online ordering demand nationwide and guaranteeing sourcing of medical supplies - quickly and without contaminating customers - have proved critical for suppliers and distributors.

Leading local e-commerce and delivery firms have deployed their latest autonomous delivery technologies to make up for the lack of human labour and overcome the fear of contact. They have redoubled their efforts to provide same-day delivery and set up a stable distribution network to guarantee the delivery of medical equipment to hospitals both nation- and worldwide.

Ensuring the sourcing and quality of medical supplies

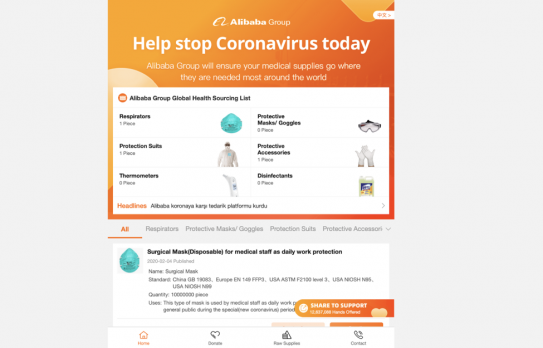

Shortly after the outbreak of the epidemic, Alibaba deployed a B2B web platform exclusively focused on the fight against coronavirus. The platform provides details on the necessary medical products and equipment, according to government and hospital recommendations. It enable suppliers of medical supplies and equipment to more quickly and effectively meet the needs of both hospitals and local authorities. Alibaba is also committed to checking that suppliers’ products meet the criteria before shipping them across China and to the rest of the world.

Source: Screenshot of the Alibaba direct sourcing platform[/caption] On 25 January, the group also invested US$ 140 million in purchasing medical equipment to meet urgent healthcare needs.

Guaranteeing quick delivery without any risk of contamination

Following the quarantining of part of the population, demand for home delivery increased, but delivery and warehouse workers were confined to their homes. So, China’s e-commerce giants had to take several measures to guarantee continuous service and fast delivery. For example, Alibaba paid available delivery and postal workers extra commission on the hours they worked and offered all sorts of businesses financial aid to cover their delivery costs. They were also given free access to Alibaba’s resource ecosystem: live video shopping services, digital delivery solutions, and online lessons from its Taobao university.

As BATX (the Chinese GAFAM) have grown into giants with a presence in all fields and industries, it’s no surprise that they are also involved in medical research. Overall, more than 30 IT and sales businesses, including the Alibaba, Tencent, and Meituan Dianping groups, respectively the equivalents of Amazon, Facebook and Deliveroo, as well as the two biggest Chinese real-estate developers, have donated US$ 432.5 million to help the government and governmental research centres to combat the virus.

Autonomous delivery to avoid human contact

In an epidemic, autonomous delivery has proved an ideal solution. Delivery robots help to calm delivery workers’ fear of human contact (in Shenzhen, an undetected infected delivery worker had worked for 14 days before being declared sick). So, the current crisis has served as a catalyst to the development of several technologies that have been tested for several months by Alibaba and other tech giants in China.

The Meituan Dianping delivery robot - Source: Handout

- The Chinese Deliveroo, Meituan Dianping, launches its robot delivery service: With the Wuhan region isolated and the risk of contamination high, Meituan Dianping decided to deploy its fleet of autonomous robots to provide last-mile delivery in Shunyi, a district of Beijing. The autonomous vehicle can carry up to 100kg of products and make between 3 and 5 deliveries a day. The business had begun testing last year but this is the first time that its robots have been spotted in public places and city centres.

JD’s first autonomous vehicle delivery - Source: JD.com

- JD.com automates last-mile delivery in Wuhan: Since February, the e-commerce giant JD.com has also been using autonomous vehicles to make deliveries to hospitals, stores, and communities in quarantined areas of Wuhan. One of the hospitals in Wuhan places between 10 and 20 orders a day, 70% of which are delivered by autonomous vehicles, size permitting.

Ele.me’s Little Peanut robot delivers meals to infected people - Source: New China TV Channel

- Ele.me delivers its ready-prepared meals using autonomous robots: Another example of implementation is the ready-prepared meal delivery giant, Ele.me, which is using robots and drones to deliver to quarantined hotel guests in Wenzhou, eastern China.

The biggest robotic warehouse in China

The country didn’t wait for coronavirus to kick in to get ahead with automating its supply chain. The autonomous technologies used in Alibaba’s warehouses are developed by the business Cainiao, in which it owns a 51% shareholding. The 160,000m² smart warehouse, located in the city of Wuxi, near Shanghai, is equipped with 700 robots, meaning it can process 50% more orders than a traditional warehouse over a given period. The few employees present on site work “hand in hand” with automated guided vehicles and robotic arms. The concept’s agility makes its design more adaptable and simplifies its deployment and relocation to new spaces. Cainiao also offers a solution to one of the biggest challenges of automation, which is traditionally less flexible than using new employees. It’s a smart system: it improves and learns constantly. The warehouse features the following technologies:

- Automated guided vehicles (AGV): they are connected via the IoT to a routing system that guides them to load and unload goods collision-free. The AGVs are able to find the right article for each order. The content of the shelves is taken to employees in a specific order, meaning they know exactly what products to put in the boxes they’re filling.

- The robotic arms are connected to AGVs: Cainiao combines 3D camera algorithms and computer vision to identify the position of objects and recognise robotic arm movements to effectively sort parcels and route them to the right shelves, conveyor belt and AGV in the warehouse.

Source: Alizila

Innovation for last-mile delivery

The smart warehouse is just one example of implementation of Cainiao’s technologies. The group is looking to digitize every stage of the supply chain so isn’t stopping there. A few of these inventions are particularly focused on the last-mile stage, which is the most expensive part of the delivery process, as well as environmental issues to make deliveries greener:

- Connected packaging: Cainiao has developed smart packaging to reduce waste due to overpackaging. The seller provides the dimensions of the products ordered, and the system recommends the right packaging, as well as the order in which to pack the products to maximise space.

- Smart letterboxes: similar to smart lockers, the concept solves the issue of time lost through repeated attempts to make deliveries when customers aren’t home. The box can be installed by consumers by their front door to take parcels or food deliveries. Equipped with its own camera, the letterbox opens using facial recognition or a mobile app. It can be used as a temporary refrigerator as its temperature can be adjusted and controlled remotely using the app.

- The Sky Eye programme: set up for Singles’ Day, the Cloud-based video control system was jointly developed by Cainiao with other supply chain partners in 2019. It connects to the country’s logistics station cameras and enables businesses to track parcels shipped in real time to solve unexpected issues as quickly as possible. The system made deliveries 15% more efficient and successful.

China’s advanced development and early adoption of the latest technologies, from automated warehouses to delivery robots, as well as smart maintenance or delivery systems, have proved key tools to contain the epidemic. It remains to be seen how the adoption of these technologies will change when the situation gets back to normal.