Predictive Ordering: Boosting Availability, Minimizing Inventory, Elevating Customer Satisfaction

Predictive ordering is the key to always having the right quantities in stock: enough for your customers but never too much. Learn how to efficiently predict demand for your products to optimise your operations and customer experience on an ongoing basis.

With predictive ordering you look at future product demand based on historical data, a variety of trends and other factors. Unlike traditional forecasting, which only gives an estimate of demand, predictive ordering also predicts when exactly that demand will occur.

The added value of predictive ordering varies by sector:

- For goods with limited shelf life - such as food - predictive ordering reduces waste. Restaurants and food service providers, for example, can order their ingredients and supplies based on menu offerings and customer traffic patterns.

- Pharmaceutical companies face regulatory requirements they have to comply with. They have to guarantee the shelf life of their products and anticipate fluctuations in drug demand, for example during flu season.

- Retailers selling consumer electronics often have to anticipate product launches and technological advances. They order their inventory before product releases so that stock is available when consumers are looking for the latest gadgets.

- The fashion industry is all about seasonal trends, fashion cycles and changing consumer preferences. Again, retailers need to order their stock well in advance of the season to ensure they have the right products in stock during busy shopping seasons, such as school holidays, holidays and specific fashion weeks. With predictive ordering, these retailers can also predict declining demand so that they need to put fewer products on sale.

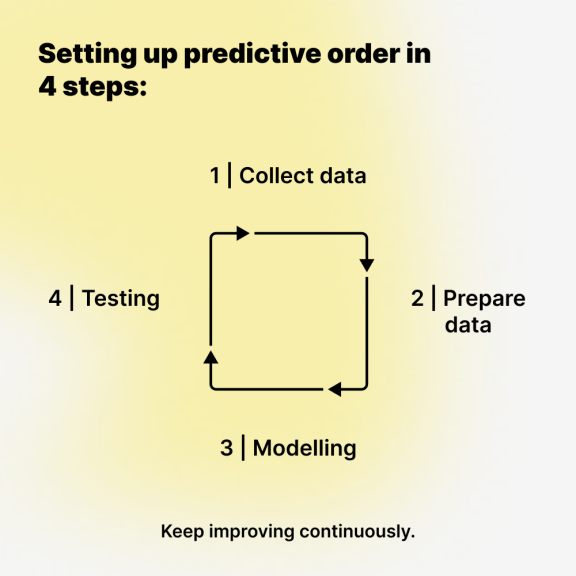

Keep improving continuously with prediction model

No prediction model will continue to work well without continuous improvements. Create a feedback loop that allows you to continuously improve data quality, add more relevant data sources or remove irrelevant data and comprehensively identify patterns. The reality of the market is constantly changing: the challenge is to follow it so regularly that your predictions keep getting better.

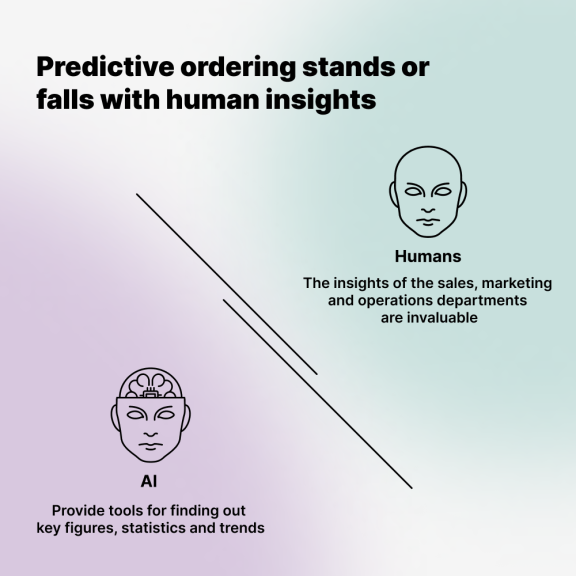

Major organisational changes also have a big impact on the forecasting model, such as new product lines or new markets being entered. Make sure the model can scale with the organisation. Even then, it is crucial to keep human insights leading. Relying too much on new technological capabilities or external specialists with insufficient knowledge of the market is a pitfall.

Finally, the most important best practice of all is to use the insights from predictive ordering to actually improve your operations. If you don't take action on your created predictions, then you are actually of little use. Make sure that an employee or department takes ownership of the realised predictions and translates them into a more effective procurement process, lower inventories, successful marketing campaigns, dynamic pricing, less overhead and, above all, a better customer experience.

Are you going for a little better every day with predictive ordering? Then your long-term success can be predicted with ease.

DID WE PIQUE YOUR INTEREST?

Get in touch to discover how we can drive your digital sucess.

Contact us